The Jewelry Manufacturing - Process Of Casting Bracelet From Beginning To End

Jewelry making is a wonderfully innovative business. There is nothing rather like making gorgeous new shapes out of precious metals and gemstones that your customers will cherish and love for years to come. Throughout the years, the wax casting procedure hasn’t just been used for jewelry, but it was also used to make sculptures and ornaments.

Also, one of the main benefits of wax casting is that you can repeat the same model as many times as you’d like. The possibilities of creation with castings are endless. The casting jewelry process captures even the most minor details and is cost and time effective; it helps you to make multiples of the same pieces.

Also, one of the main benefits of wax casting is that you can repeat the same model as many times as you’d like. The possibilities of creation with castings are endless. The casting jewelry process captures even the most minor details and is cost and time effective; it helps you to make multiples of the same pieces.

The Casting Jewelry Process: A Closer Look

Casting is a part of a similar jewelry creation process. It allows us to take an idea or design, assemble a mold, and ultimately create a physical replica of the final product.

CAD & CAM - To cast jewelry, you need a master sample. Traditionally, one used to be carved by hand to use after in the model-making process. But, unquestionably, computers have changed the landscape of every industry, and a clear illustration of this is the method & technology being used in CAD jewelry designs. Artisans develop CAD jewelry designs on computer screens using equipment and software that metamorphose their thoughts and keystrokes into creations of art. These are then transformed from data to a 3D wax or resin form.

CAD & CAM - To cast jewelry, you need a master sample. Traditionally, one used to be carved by hand to use after in the model-making process. But, unquestionably, computers have changed the landscape of every industry, and a clear illustration of this is the method & technology being used in CAD jewelry designs. Artisans develop CAD jewelry designs on computer screens using equipment and software that metamorphose their thoughts and keystrokes into creations of art. These are then transformed from data to a 3D wax or resin form.

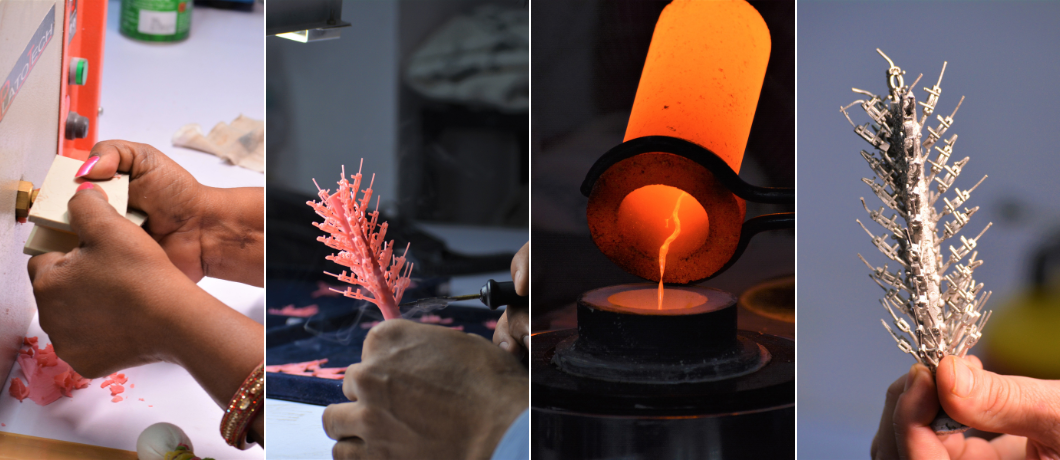

Wax model - Using the CAD design, a liquid dye is made, and a wax model is carved or printed to illustrate the finished piece in three dimensions. Then a rubber mold is crated with a 3D design and is injected with wax to create the jewelry piece form. After the wax hardens up, it is removed and inspected for quality.

Casting Preparation - These are joined to a wax stem by a sprue. This will form the canal through which the molten silver will flow once the mold is created. Numerous wax models can be attached to form a tree or left as single models and placed in a cylinder mold. Building a tree allows the jeweler to cast multiple jewelry pieces at once.

POP Flask - The wax stem and the attached models are placed in a unique frame called a flask and is surrounded by an investment material called POP. The cylinder is filled with investment to cover the wax completely. Once the investment material like POP sets, it hardens into the mold for the jewelry. Vacuum pressure is created to remove all the air bubbles from the cylinder to make a perfect mold. Any air bubbles compromise the quality of the casting.

Burnout - After the Plaster of Paris material hardens, the flask is placed in a special kiln to boil away the wax, which leaves a hollow in the POP material that becomes the final mold. The mold now has a tree-shaped cavity that is ready for casting.

Melting - The silver is melted, and depending on the type of metal used, temperatures can range from 1,617 degrees Fahrenheit and 2,006 degrees Fahrenheit. Silver can be combined with other metals like gold, copper, and palladium to create alloys of varying colors and hardness.

Casting - In this step, the precious metal of your choice is melted and poured into the plaster mold. The liquid metal is then flowed into the mold to ensure a higher-quality casting. The metal, like silver, flows into every area of the mold evenly. Once the molten silver is poured into the cast, it is kept aside for cooling, and metal replicas are removed from the flask.

Divesting - Once the metal cools, it needs to be removed from the investment material. This is done through physical means by first quenching in the water while it is still hot and then putting it under the pressure of water to remove all the bits and pieces of POP. Each casting is then cleaned and polished, and the sprues are cut- off for recycling.

Finishing - The sprue and other extra metal will be trimmed away, but many imperfections will stay. There might be edges and seams to grind out, specifically if it was made with multiple castings in a tree formation. Now remove the sprue, polish the jewelry piece, do the rhodium or gold plating, and finally set it with the perfect gem.

Tumbling - The next step in finishing your jewelry castings is tumble finishing. Tumbling is a method where your piece is “tumbled” around a cask with other materials to clean, smooth, and illuminate it, bringing it one step closer to the final piece.

The cask of the device is filled with whatever medium you choose and a lubricant like water and then rotated to tumble the materials together. As a result, your jewelry pieces will appear smoother and shinier with each round.

Polishing - Polishing is a stage where any remaining flaws are removed, and your castings are thoroughly groomed and polished to a brilliant shine.

Jewelry shops all over the world trust Gemexi to provide superior quality handmade and casting jewelry. We have vast experience in using the latest technology and casting equipment and our personalized approach to customer assistance. Some of the reasons why customers have preferred us for their jewelry needs:

- • Use of a multi-step quality verification process

- • Opportunity to use multiple jewelry designs in one place

- • Use of high-quality technologies and cutting-edge molding.

- • Capability to create designs in the silver metal itself, gold & rhodium plated.

- • Fast turnaround on casting orders

- • Using a variety of gemstones in similar designs

- • Ability to accept bulk orders for jewelry shops around the world

- • Use of authentic gemstones and genuine 925 sterling silver

- • You will have a personalized customer support coordinator who will work with you to place your order and match you with the services you need to get an outstanding service, from placing an order to delivering your parcel.

Advantages of Casting Jewelry Process

- Lower Costs - As you may already know, producing jewelry is not a cheap or easy labor, especially if you are starting. You require a lot of precious material and specialized tools to create custom castings. Expanding your business shouldn’t deplete your savings and your well-earned revenue. When you outsource your jewelry casting requirements to Gemexi, you get expert services at a competitive rate. We already have everything you need to create stunning jewelry. All you have to do is drop us a mail and tell us what you need.

- Save Time - Even if you already have the required equipment and materials for jewelry making, you might likely not be equipped or experienced enough to endure the workload of mass production. As a shop owner or designer, your time and energy are priceless. Use your time to dream up new outcomes and innovations and expand your business.

- Maintain Quality - We understand that delegating a third-party company with your jewelry can be nerve-wracking. That’s why Gemexi is committed to quality and authenticity. We have existed in the jewelry business for more than 40 years, and for each one, we have committed ourselves to developing the absolute best handmade and casting jewelry we can. We combine traditional experience with new technology to bring you the best possible jewelry pieces, and each order gets the individualized attention it deserves. Our goal is to bring your extraordinary designs to life with our high-quality craftsmanship.

Choose Gemexi for Complete Jewelry Manufacturing

We can create stunning custom casting jewelry for your business and can help you find the perfect final product. Our complete jewelry manufacturing process gives you the benefits of die-cutting, casting, stone setting, polishing, and engraving. And it is ready!! Gemexi offers all the handmade and casting jewelry products, and be sure to stop by our location at Jaipur to select the perfect piece!